Services

Consultancy

Transparency from the outset. We work with you to discuss the process we will use to produce your parts and provide various tips and suggestions. This lays the groundwork for a smooth workflow. This transparency creates a high level of production reliability right from the start.

Development

We take your ideas and develop all of the necessary processes with an optimal design of your component(s) by our team to ensure smooth and economical mass production. We also bring the expertise and computing power to create your design digitally.

CAD: making ideas ready for production. Not only through the exchange of data exchange, but also on-going communication throughout the production process is the foundations of a successful partnership. We can handle a full range of formats for your design, include step files, IGES, etc.

Production

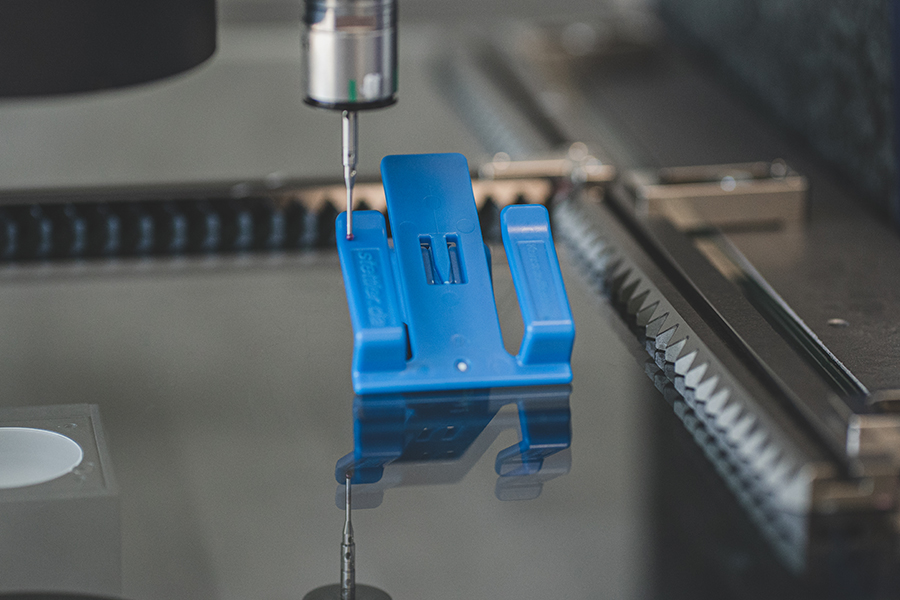

Tool types tailored to production. We work with different types of tools: simple tools, multi-cavity moulds, and even 64-fold, multiple-component tools for up to three components.

Machines: the right solution for every task. Our machinery includes more than 60 injection moulding systems that offer anywhere from 80 to 350 tonnes of clamping force. Single-component and multi-component machines combined with a high degree of automation are the basis of our production.

Automation. Large batch sizes and a zero-defect philosophy are possible only with fully automated production precisely tailored to your product. Individual production components precisely matched to guarantee a smooth production process.

Assembly. Components are assembled as required.

Quality Management

We are ISO 9001, ISO 14001, ISO 50001 and IATF 16949 certified.

Environmental and energy-saving expertise. We are committed to complying with all applicable laws and other requirements designed to protect our environment and save energy through continuous improvement and greater efficiency. We focus on purchasing the most environmentally friendly and energy efficient products and services to improve our environmental and energy-efficient performance. We have defined a matrix of environmental and energy goals and consistently pursue their achievement by providing the necessary personnel and financial resources.

Workplace safety. Health is a person’s most valuable possession. It is our stated aim of preserving this for the benefit of our employees and of the company. We therefore want to do everything appropriate to ensure the health of our employees and motivate them to take care of their health both at work and at home. We view safety and environmental protection as absolute prerequisites for our economic success. Safety and environmental protection means that we implement processes that minimise the health and safety risks for our employees and the environmental impact of our work.

Logistics

A standard part of our work. Whether just-in-time, consignment stock, 24 hour-ordering, or Kanban, they’re all a part of our day-to-day work.

Romania

Hand in hand. Since 2006 we can also offer support from our Stettler Tech branch in Romania.